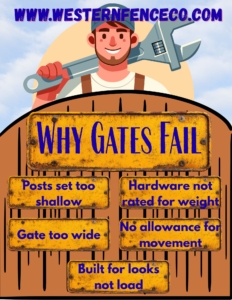

Why Gates Fail (And How to Make Sure Yours Doesn’t)

Gates are often the most used and most stressed part of any fence system. They are opened daily, exposed to weather year round, and expected to stay aligned while carrying significant weight. When a gate fails, it usually is not sudden or mysterious. It is the result of a few common mistakes made at the beginning.

Here are the real reasons gates fail and what should be done differently.

Posts Set Too Shallow

A gate is only as strong as the posts holding it. One of the most common failures we see is posts that were not set deep enough for the weight and movement of the gate.

Gate posts need to resist not just vertical load, but constant lateral force from opening, closing, wind, and ground movement. Shallow posts shift over time, which leads to sagging, dragging, and misalignment. Once a post moves, the gate follows.

Depth matters. So does proper footing size and soil consideration. This is not an area to cut corners.

Hardware Not Rated for the Weight

Heavy gates require hardware designed to carry heavy loads. Decorative hinges or light duty hardware may look good on install day, but they are not built for long term performance.

Underrated hardware wears out quickly, bends under stress, or fails altogether. Proper hinges, latches, and fasteners should be selected based on gate size, material, and frequency of use, not appearance alone.

Gate Too Wide

Wide gates are visually appealing, but width dramatically increases leverage and stress on posts and hardware. The wider the gate, the more force is applied every time it moves.

Many gate failures happen because the span was pushed too far without compensating with structural support, reinforced framing, or additional posts. Good gate design balances access needs with structural reality.

No Allowance for Movement

All materials move. Wood expands and contracts. Metal shifts with temperature. Soil heaves and settles. Gates that are built too tight with no tolerance for movement will bind, drag, or twist over time.

Allowances for seasonal movement and daily use are not flaws. They are intentional design decisions that keep gates functioning smoothly long term.

Built for Looks, Not Load

This is one of the biggest problems we see. A gate can look beautiful and still be structurally wrong.

When design prioritizes appearance over load bearing requirements, failure is only a matter of time. A properly built gate considers weight distribution, internal framing, hinge placement, and long term stress first. Aesthetics should complement structure, not replace it.

The Bottom Line

Most gate failures are not accidents. They are predictable outcomes of poor planning, improper materials, or shortcuts during installation.

A well built gate should open smoothly, stay aligned, and perform for years without constant adjustment. That only happens when it is designed and built with structure in mind from the start.

If you are investing in a custom gate, make sure it is built for load, movement, and longevity, not just the photo on install day.

Because the gates you notice most are the ones that stop working.